Physical Properties and Compliance with UK Building Regulations

The following technical information is also available for download as a PDF file here.

Stabilised rammed earth (SRE) can successfully be used to conform to the Building Regulations (2000) for England and Wales as an acceptable alternative form of low-rise masonry construction in public and residential buildings. Recommendations for how this can be achieved are given through the case study by the Planning Department of Chesterfield Borough Council (ref: Hall, Damms & Djerbib, 2004).

Regulation 7 - Materials and Workmanship

At present there are no officially recognised codes of practice for rammed earth construction in the United Kingdom. The fitness of SRE materials is currently established under:

a) Tests and calculations, and

b ) Past experience

Suitability and classification of soil materials is established in accordance with:

BS 1377-2: 1990 - Soils for Civil Engineering Purposes - Part 2: Classification Tests, British Standards Institute, London

BS 1377-4: 1990 - Soils for Civil Engineering Purposes - Part 4: Compaction Related Tests, British Standards Institute, London

.

A series of 100mm SRE cube samples are produced in a laboratory using the prescribed mix design in accordance with the guidelines prescribed in:

Hall M and Djerbib Y, 2004b, "Rammed Earth Sample Production: Context, Recommendations and Consistency", Construction and Building Materials, 18 [4] pp.281-286. N.B. Based upon BS 1881 for concrete materials

.

The curing shrinkage and estimated construction tolerances are calculated based upon:

BS EN 772-16: 2000 Methods of Test for Masonry Units - Part 16: Determination of Dimensions, British Standards Institute, London

.

Cube samples are tested for compressive strength in accordance with the guidelines prescribed in:

Hall M and Djerbib Y, 2004b, "Rammed Earth Sample Production: Context, Recommendations and Consistency", Construction and Building Materials, 18 [4] pp.281-286. NB Based upon BS 1881 for concrete materials.

Cube samples can also be tested for other physical properties depending upon the application, e.g. moisture absorption, acoustic, thermal etc.

Approved Document A - Structural Stability

For the purpose of assessment under Part A (structural stability) of the Building Regulations, SRE walls can simply be treated as a high density mass walling element.

Test Specimens

All SRE test specimens are characterised and produced as 100mm cube samples using the methodologies proposed by Hall M & Djerbib Y, 2004, "Rammed Earth Sample Production: Context, Recommendations and Consistency",Construction and Building Materials, 18 [4] pp.281-286.

Compressive strength

Minimum characteristic unconfined compressive strength (f 'cu) = ≥ 3.5 N/mm2 Typical range of f 'cu =3.5 N/mm2 to 12 N/mm2.

N.B. The f 'cu can be increased by altering the soil grading, the cement content, the ramming and the curing procedures.

Density

Typical dry density (ρd) = 2000 to 2100 kg/m3 (at 98% of Proctor compaction) Tested in accordance with BS 1377-4: 1990 - Soils for Civil Engineering Purposes - Part 4: Compaction Related Tests.

Fixing capacity

300mm Hilti C10 epoxy holds 2,000kg pull, Amdel Report No. M1034/87.

For further details of compliance please refer to:

Hall M, Damms P & Djerbib Y, 2004, "Stabilised Rammed Earth (SRE) and the Building Regulations (2000): Part A – Structural Stability", Building Engineer, 79 [6] pp. 18-21

.

Approved Document B - Fire Safety

SRE is classified as a "non-combustible material".

Fire resistance rating = 4 hours.

Tests performed by CSIRO Report No. 1839.

Approved Document C4 - Resistance to Weather and Ground Moisture

SRE walls are constructed using standard practices for DPC & DPM installation

Experimental testing has revealed that SRE easily conforms to the Building Regulations in this country;

Hall M & Djerbib Y, 2004, "Moisture Ingress in Rammed Earth: Part 2 – The Effect of Particle-Size Distribution on the Absorption of Static Pressure-Driven Water", Construction and Building Materials

Water Absorption Properties

Pressure-driven moisture absorption:

Initial surface absorption after 10 min (6% cement content) = 1.90 to 9.95 ml/m2 sec

Capillary absorption:

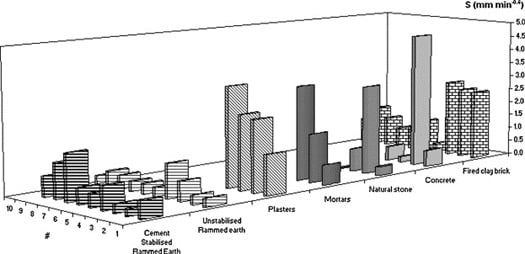

Typical Sorptivity (S) value = 0.251 to 1.631 mm min-0.5

Initial rate of suction (6% cement content) = 0.29 to 1.47 kg/m2 min (Compare with conventional materials using graph below)