|

|

|

|

|

|

|

|

|

|

| |

|

|

The following technical information is also available for

download as a PDF file here.

Stabilised rammed earth (SRE) can successfully be used to

conform to the Building Regulations (2000) for England and

Wales as an acceptable alternative form of low-rise masonry

construction in public and residential buildings. Recommendations

for how this can be achieved are given through the case

study by the Planning Department of Chesterfield Borough

Council (ref: Hall, Damms & Djerbib, 2004).

|

|

|

|

| Regulation 7 - Materials

and Workmanship |

|

|

| At

present there are no officially recognised codes of practice

for rammed earth construction in the United Kingdom. The

fitness of SRE materials is currently established under:

a) Tests and calculations, and

b ) Past experience

Suitability and classification of soil materials is established

in accordance with:

BS 1377-2: 1990 - Soils for Civil Engineering Purposes - Part 2: Classification Tests, British Standards Institute, London

BS 1377-4: 1990 - Soils for Civil Engineering Purposes - Part 4: Compaction Related Tests, British Standards Institute, London

.

A series of 100mm SRE cube samples are produced in a laboratory

using the prescribed mix design in accordance with the guidelines

prescribed in:

Hall M and Djerbib Y, 2004b, "Rammed Earth Sample

Production: Context, Recommendations and Consistency",

Construction and Building Materials, 18 [4] pp.281-286.

N.B. Based upon BS 1881 for concrete materials

.

The curing shrinkage and estimated construction tolerances

are calculated based upon:

BS EN 772-16: 2000 Methods of Test for Masonry Units

- Part 16: Determination of Dimensions, British Standards

Institute, London

.

Cube samples are tested for compressive strength in accordance

with the guidelines prescribed in:

Hall M and Djerbib Y, 2004b, "Rammed Earth Sample

Production: Context, Recommendations and Consistency",

Construction and Building Materials, 18 [4] pp.281-286.

NB Based upon BS 1881 for concrete materials.

Cube samples can also be tested for other physical properties

depending upon the application, e.g. moisture absorption,

acoustic, thermal etc.

|

|

|

|

| Approved Document A - Structural Stability |

|

|

| For

the purpose of assessment under Part A (structural stability)

of the Building Regulations, SRE walls can simply be treated

as a high density mass walling element.

Test Specimens

All SRE test specimens are characterised and produced as

100mm cube samples using the methodologies proposed by Hall

M & Djerbib Y, 2004, "Rammed Earth Sample Production:

Context, Recommendations and Consistency",Construction

and Building Materials, 18 [4] pp.281-286.

Compressive strength

Minimum characteristic unconfined compressive strength (f

'cu) = ≥ 3.5 N/mm2 Typical range of f

'cu =3.5 N/mm2 to 12 N/mm2.

N.B. The f

'cu can be increased by altering the soil

grading, the cement content, the ramming and the curing

procedures.

Density

Typical dry density (ρd) = 2000

to 2100 kg/m3 (at 98% of Proctor compaction) Tested in accordance

with BS 1377-4: 1990 - Soils for Civil Engineering Purposes

- Part 4: Compaction Related Tests.

Fixing capacity

300mm Hilti C10 epoxy holds 2,000kg pull, Amdel Report No.

M1034/87.

For further details of compliance please refer to:

Hall M, Damms P & Djerbib Y, 2004, "Stabilised

Rammed Earth (SRE) and the Building Regulations (2000):

Part A – Structural Stability", Building Engineer,

79 [6] pp. 18-21

. |

|

|

|

| Approved Document B - Fire Safety |

|

|

| SRE

is classified as a "non-combustible material".

Fire resistance rating = 4 hours.

Tests performed by CSIRO Report No. 1839.

|

|

|

|

| Approved Document C4 - Resistance to Weather and Ground Moisture |

|

|

| SRE

walls are constructed using standard practices for DPC &

DPM installation

Experimental testing has revealed that SRE easily conforms

to the Building Regulations in this country;

Hall M & Djerbib Y, 2004, "Moisture Ingress in

Rammed Earth: Part 2 – The Effect of Particle-Size Distribution

on the Absorption of Static Pressure-Driven Water",

Construction and Building Materials

Water Absorption Properties

Pressure-driven moisture absorption:

Initial surface absorption after 10 min (6% cement content)

= 1.90 to 9.95 ml/m2 sec

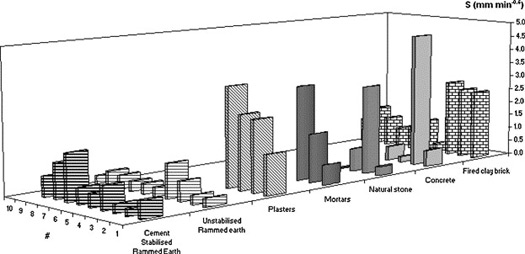

Capillary absorption:

Typical Sorptivity (S) value = 0.251 to 1.631 mm min-0.5

Initial rate of suction (6% cement content) = 0.29 to 1.47

kg/m2 min (Compare with conventional materials using graph

below)

Graph: adapted from Hall M & Djerbib

Y, 2005, "Moisture ingress in rammed earth: Part 3 -

Sorptivity, surface receptiveness and surface inflow velocity", Construction

and Building Materials. |

|

|

|

| Durability Properties |

|

|

| Durability

of SRE materials is determined using the 'accelerated erosion

test' (AET) in accordance with Standards New Zealand, 1998,

NZS 4298: 1998 Materials and Workmanship for Earth Buildings,

Wellington, New Zealand

AET value for SRE = 0.0 mm/min

Tests performed by Materials Consultants Aust. Pty. Ltd.

Report No. 202/87

Please note: Unstabilised rammed earth

walls may not be compliant under Building Regulations.

Both Regulation 7 and Approved Document C categorically

state that external masonry walls on a building must:

Not

be damaged by rain or snow

Resist the passage of rain (or snow) to the inside of

the building

Not transmit moisture

due to rain (or snow) to another part of the building that

might be damaged |

|

|

|

| Approved Document E - Resistance

to the Passage of Sound |

|

|

| In

order to demonstrate compliance "laboratory values

for new internal walls and floors within: dwelling-houses,

flats and rooms for residential purposes, whether purpose-built

or formed by material change of use" must have a minimum

Rw of 40 dB (Rw = weighted sound reduction index)

Example: an SRE wall; Assuming a wall thickness of

300mm the typical Rw of the wall = 58.3 dB |

|

|

|

| Approved Document L1 - Conservation

of Fuel and Power in Dwellings |

|

|

|

SRE buildings can be assessed either using the target U-value

method, the Carbon Index method or the elemental method.

The walls can be constructed in 3 different Part L-compliant

configurations:

1. Solid SRE wall with external insulated cladding + render

2. Solid SRE wall with internal dry lining

3. Cavity SRE wall with solid-foam cavity insulation

Example:

For a cavity SRE wall with 175mm SRE inner & outer leaves

incorporating polyisocyanurate solid cavity insulation and

stainless steel wall ties;

Calculated U-value = 0.335 W/m2 K (for 50mm thick insulation)

Or, = 0.245 W/m2 K (for 75mm thick insulation)

SRE walls also have very high thermal capacitance (i.e.

"thermal mass")

Typical value for a 300mm wall = 1673 KL/m3K

Approximate thermal time lag = 6 - 8 hours |

|

|

|

|